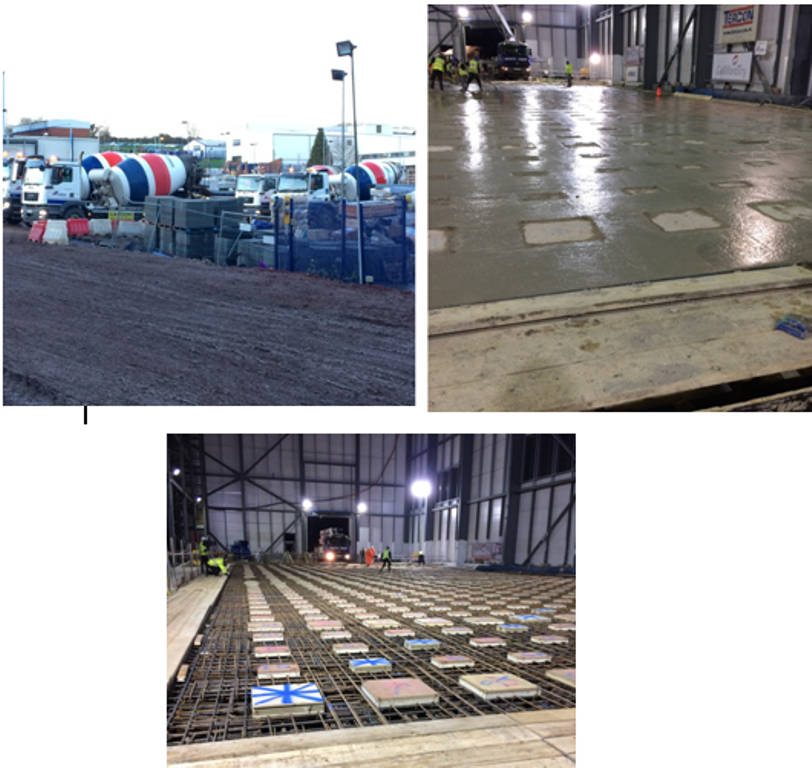

December saw CEMEX undertake a large and highly publicised project for Airbus in Bristol. All three of the Area Plants: Bristol, Henbury and Wickwar, exclusively served and successfully completed a 1,450m3 24-hour continuous pour. The main contractor for the project was Galliford Try and the subcontractor for the floor was Tercon, a Bristol based local groundworker.

This pour was a UK first as it was being poured for a slab known as a ‘strongfloor’. The purpose of this new floor was to allow the UK to become a hub for new airplane wing testing that will be used across the world. The project was heavily funded by the UK Government and saw 13 weeks’ worth of complex steel and rebars being installed by Tercon prior to the pour. There are only three known strongfloors in the world with this being the first in Europe.

The pour was covered by the BBC, Bristol Post, Galliford Try media and Airbus media. It has been branded one of the largest continuous pours in the UK for 2017 and the largest single concrete pour in Bristol to date. Tercon are a groundworker we have been working with very closely with over the past 12 months.

The project created several challenges that were overcome through meticulous planning, teamwork and clear lines of communication across all involved.

Sam Ryan, RMX Sales Manager, talks us through it: “By working as one CEMEX all the Aggregate and Cement deliveries were on time and excellently planned so the flow of concrete was continuous. Area 20 pulled together to ensure success with both the Shipping Office Manager, Richard Dytor, and Sales Manager, Sam Ryan, manning the phone throughout the pour should anything unexpected occur. Ops Manager, Andrew Hoskins, spread his time across the Plants to ensure production was smooth. Sales Executive, Gregory Vaughan, gave a CEMEX representation on site for the full 24 hours and Technical Manager, Stephane Plisson, dedicated all his time to being on site checking quality throughout the day and evening.

A special thank you goes to all the batchers, fitters, and electricians in Bristol, Henbury and Wickwar, along with the 38 mixer drivers that were paramount to the eventual success of the pour.”