Hazard Identification and Risk Assessment is a key part of our Health and Safety Management System (HSMS). This process helps us spot potential hazards and figure out how likely and serious the risks are before they turn into incidents.

Element 2 of our Cemex Health and Safety Management System (HSMS) contains full details (click here to access: HSMS). Please familiarise yourself with it but contact your local Health & Safety specialist for further advice and guidance if it’s needed.

Please print and display the Risk Assessment poster on your Health & Safety notice boards. You can find it on the UK News download page: here

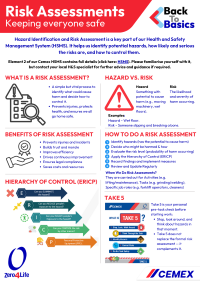

What is a Risk Assessment?

A risk assessment is a simple but vital process we use to keep people safe at work. It involves looking at a job, task, or work area, identifying what could cause harm, and deciding what we need to do to control it. It’s not just paperwork — it’s about preventing injuries, protecting health, and making sure we all go home safe.

Hazard vs. Risk

It’s important to understand the difference:

| Hazard | Risk |

| Something with the potential to cause harm (e.g., moving machinery, working at height, chemicals). | The chance that the hazard will cause harm, and how serious the outcome could be. |

Example:

Hazard: A wet floor.

Risk: Someone slipping, falling, and breaking a bone.

Benefits of Effective Risk Management:

When we manage risks well we can spot potential problems early and deal with them before they become big issues. This helps keep everyone safe and the business running smoothly. The benefits include:

- Injury and Incident Prevention: By spotting hazards early we can put measures in place to stop incidents before they happen. So everyone goes home safely.

- Improved Morale and Engagement: A safe workplace builds trust and confidence among everyone. When people see that their safety is a priority, they’re more likely to be engaged and productive.

- Enhanced Operational Efficiency: Knowing the risks helps us plan better and use resources more effectively. This streamlines processes, cuts down on waste, and boosts overall efficiency.

- Continuous Improvement: Risk assessment isn’t a one-time thing—it’s an ongoing process. Regular assessments help us adapt to changes in operations, technology, and workforce dynamics.

- Legal and Regulatory Compliance: Conducting and regularly reviewing risk assessments ensures we comply with health and safety laws. This helps us avoid fines, legal issues, and damage to our reputation.

- Cost Reduction: Preventing incidents saves money on medical expenses, insurance premiums, compensation claims, and equipment damage. It also reduces productivity losses due to absenteeism or operational disruptions

How to Carry Out a Risk Assessment

A workplace risk assessment is a systematic process used to identify hazards, evaluate risks, and implement measures to control or eliminate them.

Key Steps:

- Identify Hazards (something with the potential to cause harm)

- Determine Who Might Be Harmed and How

- Evaluate Risks (probability of harm occurring i.e. the chance of an injury)

- Determine control measures by applying the Hierarchy of Control – ERICP

- Record Findings and Implement Measures

- Review and Update Regularly

Make sure to share the relevant findings from risk assessments with everyone who needs to know. Remember, risk assessments should be reviewed regularly, at least once a year, and whenever there are changes like new staff, new equipment, or new processes etc.

When We Do Risk Assessments

Risk assessments are carried out for:

- Activities (e.g., lifting operations, maintenance work)

- Tasks (e.g., grinding, welding, loading materials)

- Specific job roles (e.g., forklift operators, cleaners, maintenance staff)

Hierarchy of Control:

Elimination (E): This is the most effective method. It involves completely removing the hazard from the workplace. For example, if a machine is dangerous, eliminating it means getting rid of the machine altogether.

Elimination (E): This is the most effective method. It involves completely removing the hazard from the workplace. For example, if a machine is dangerous, eliminating it means getting rid of the machine altogether.- Reduction (R): This step involves reducing people’s exposure to the hazard. This could mean limiting the amount of time workers spend near the hazard or reducing the number of people who come into contact with it.

- Isolation (I): This involves isolating people from the hazard. For instance, placing a barrier between the hazard and the workers or using remote controls to operate machinery from a safe distance.

- Control (C): This step involves implementing other control measures to reduce the risk. This could include using safety guards on machinery, implementing safety procedures, or providing training to workers.

- Personal Protective Equipment (PPE) (P): This is the least effective method and should be used as a last resort. It involves providing workers with personal protective equipment like gloves, masks, or helmets to protect them from the hazard.

By following this hierarchy workplaces can effectively manage hazards and ensure the safety of their employees.

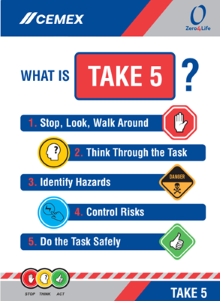

Take 5

Our Take 5 process is here to help you make sure everything’s safe before you start a task. It’s a quick personal check that only takes a few minutes but can prevent injuries.

Our Take 5 process is here to help you make sure everything’s safe before you start a task. It’s a quick personal check that only takes a few minutes but can prevent injuries.

Take 5 is your personal pre-task check before starting work:

- Stop, look around, and think about hazards in that moment.

- Take 5 does not replace the formal risk assessment — it complements it.

Make it a habit!